LAURYL GLUCOSIDE (LG) 50%, L

7.80 €

Lauryl glucosides, CAS 110615-47-9, LG, INCI LAURYL GLUCOSIDE, alkyl polyglucosides, alkyl C12 polyglycosides, didecyl glucosides, lauryl glucoside, poly(laurylglucoside)-7.

Parameter | Attribute |

Lauryl glucoside | Lauryl glucosides, APG, alkyl poly glucosides, alkyl C12 polyglucosides, didecyl glucosides, lauryl glucoside, poly(laurylglucoside)-7 |

Formula | Mix |

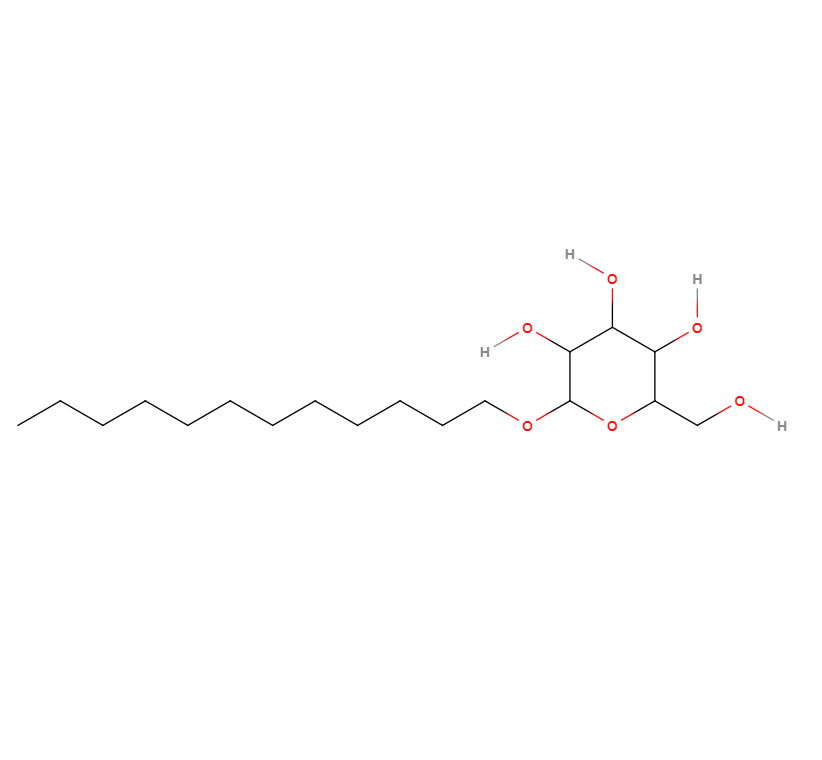

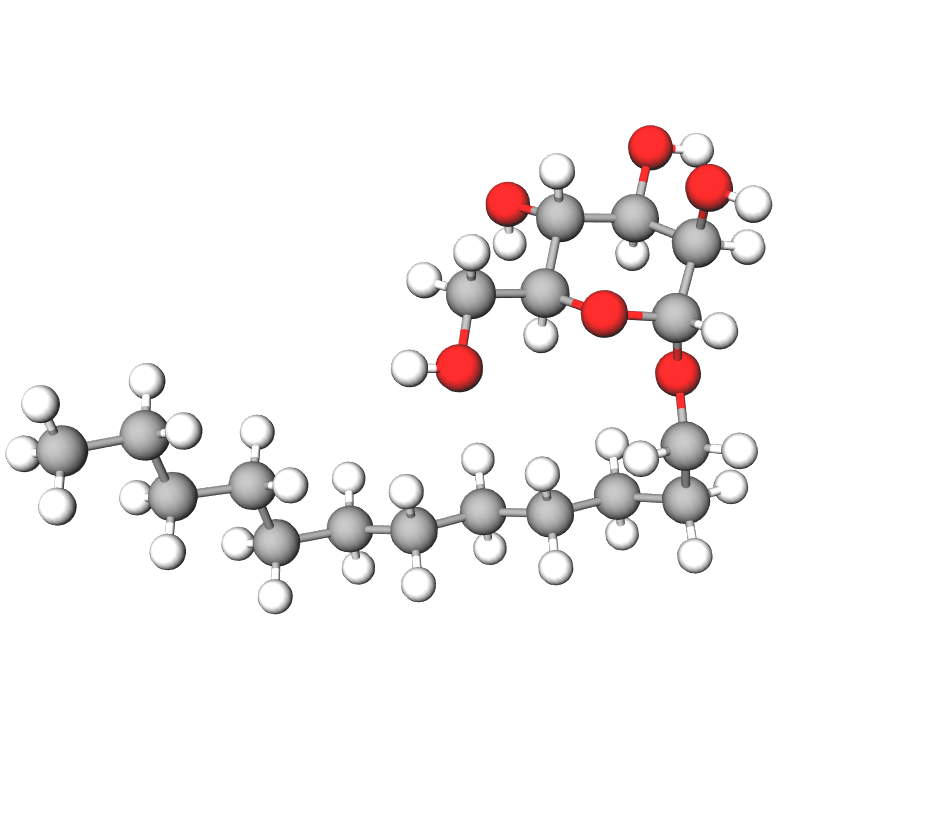

Structure |   |

IUPAC | D-Glucopyranose, oligomeric, C12-alkyl glycosides |

INCI | LAURYL GLUCOSIDE |

CAS | 110615 47 9 |

Molar mass | Mix |

Density | 1,10 g/mL 20 °C |

Solubility | Miscible with water and most polar solvents |

Lauryl glucoside acts as a surfactant and foaming agent. It is made from renewable raw materials and is easily biodegradable. It is easy to thicken and has excellent foaming properties. Free of ethoxylates, sulphates and preservatives. It improves the quality of the foam and gives a smooth and transparent formula. It is compatible with many other surfactants, thickeners and even cationic conditioning polymers. It is gentle on skin and hair. It is cold processable and suitable for transparent formulations. It complies with ECOCERT and COSMOS standards. A water-miscible non-ionic surfactant used in a wide range of applications including hard surface and high performance cleaners, cosmetics, it has excellent wetting and excellent grease removal properties, dissolves quickly, has no gel range and rinses well. It is commonly used as a water-soluble emulsifier.

Advantages:

- Easily biodegradable

- Provides performance analogous to that of nonylphenol ethoxylate (NPE) surfactants and in most cases performs better than primary alcohol ethoxylate (PAE) surfactants.

- Excellent wetting performance

- Water soluble

- Soluble in most polar organic solvents

- Cold production

- Chemically stable in dilute acids, bases and salts

- Compatible with anionic, cationic and other non-ionic surfactants

In cosmetics, lauryl polyglucosides or LAPG (LG) are used as surfactants of non-ionic nature. They are considered as a new generation of green surfactants that are considered non-allergenic, moisturizing and produced from renewable sources. Lauryl glucosides are used in various cosmetic formulations due to their gentleness and safety on sensitive skin. Lauryl glucoside produces an excellent and stable foam. Lauryl glucoside is useful in hair care products where it helps to cleanse the hair without drying it out. Lauryl glucoside can be used in combination with other glucosides to improve the foaming and skin conditioning properties. Lauryl glucoside is very effective when used in ionic formulations to increase foam depth and emulsifying properties. Lauryl glucoside is very useful in bath foams, shower gels and shampoos when you want to increase the lathering of the product without compromising the natural formulation. Concentrations ranging from 2% to 20% are used, depending on whether it is used as a primary or secondary surfactant. For example: 10% to 20% (in face wash), 15% to 30% (shower gel, bath foam, shampoo). Maximum recommended concentration up to 40%.

In the cleaning industry, LG is used in the production of hard surface cleaners, strong-acting cleaners, concentrates. Due to its strong wetting properties and good emulsifying properties, it is excellent at allowing the water and the grease phase to mix, thus facilitating cleaning processes. Its high foaming properties make it ideal for use in the production of active foams. Due to its natural nature, it is ideal for use in cleaning products that are used outdoors and may come into contact with nature.

In paints and coatings, lauryl glucoside is used to increase the wetting effect of the surface in order to achieve better adhesion to the surface, while at the same time facilitating the mixing of the fatty phase ingredients with the aqueous phase ingredients.

In agriculture, LAPG is used to spray fields and plants with a variety of products in order to increase the efficiency of foliar uptake. Alkyl polyglucoside is analogous to polyglucosides in plant cell membranes and therefore wets the leaf surface, making it easier for the spray to adhere to and remain on the leaf, thereby increasing contact time and uptake efficiency. At the same time, it allows a more even distribution of the active substances, which are often hydrophobic and tend to persist in two different phases.

In the textile industry, it is used to clean heavily contaminated fabrics from soiling of fatty or protein origin.

In the paper industry, it is used in the formulation of paper to obtain better adhesion, denser structure.

In school experiments, oxirane is used in surface wetting experiments, "magic milk" art experiments. In scientific research, it is used to study the permeability of cell membranes, as APG is naturally found in cells of plant origin.

Important: Add the item to your basket, fill in the recipient's details and confirm your order. Thank you!

To save your precious time, we will deliver your order to your address at a time convenient for You!

*- Pictures of the goods may not reflect the actual appearance, color, assembly or shape of the goods and their packaging. The information in the product description is general and may not correspond to the information on the packaging of the product and may not be accurate as to the use of the product. The information given on the stocks and prices of goods may, in certain cases, differ from the actual prices and stocks of goods

Signal word: Danger |

Hazard icons:

|

Danger phrases: H315 Irritating to skin H318 Causes eye damage |

Precautionary statements: P264 Wash hands thoroughly after use P280 Wear protective gloves/protective clothing/eye/face protection. P302+P352 IN CASE OF CONTACT WITH SKIN: wash off with plenty of soap and water. P332+P317 In case of skin irritation: seek medical advice. P362 Remove contaminated clothing and wash before putting it back on P305+P351+P338 IN CASE OF CONTACT WITH EYES: Wash gently with water for several minutes. Remove contact lenses, if present and if easy to do so. Continue to wash eyes. |

Related products

(8 other products in the same category)